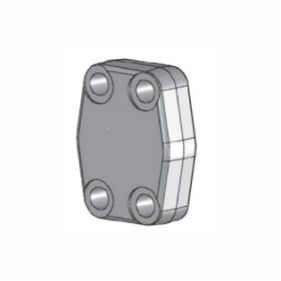

Pipe Fittings

Hydraulic fittings are parts used to connect hoses, pipes, and tubes in hydraulic systems. Hydraulic equipment generally operates under high pressures and is often not a fixed system. Consequently, hydraulic fittings need to be strong, versatile, and reliable to operate safely and effectively in their respective applications. These fittings typically adhere to strict standards which dictate fitting construction, dimensions, and pressure ratings.

Product Description

Threaded fittings have screw threads (built-in grooves) on their inner (female) or outer (male) surfaces designed to accept connections with matching threads. Threads which provide a simple connection but no seal are called straight threads. Tapered threads are designed to provide a tight seal for gases or fluids under pressure. Seal reliability can be improved by adding a coating or seal tape (Teflon). Especially precise threads are called “dry fit”, meaning they seal without the need for an additional sealant, which is important in applications where sealant addition could cause contamination or corrosion.

The thread size is measured and based on the inside of the vessel. Thread size standards include NPT (National Pipe Thread) and BSP (British Standard Pipe), though other standards exist and usage often varies by country and industry. Each standard corresponds to a particular number of threads per inch (TPI). Plumbingsupply.com provides an excellent overview on pipe thread sizing.